| Standard Specifications | |

|---|---|

| Equipment Series | Fltec-S Series |

| Wafer Diameter | φ380mm(φ610mm) |

| Wafer Rotation | 0-200 RPM (Revolutions Per Minute) |

| Wafer Cooling Method | Constant Temperature Water Circulation Method |

| Feed Speed of Surface Teeth | 0-500 mm/min |

| Swing Stroke | 0 to 30 mm (0 to 45 mm) |

| Number of Drives | 2 Axes/Stepless Speed |

| Minimum Cutting Amount | Minimum 0.01 mm|

| Drive Method | Belt Drive |

Fltec-M系列

- It is a packaging machine used for mass production, primarily for equipment components that require flat surfaces.。 It is used for finishing with uniform surface roughness after material grinding and for planar sliding surfaces of sealing materials.。 Compared to the S series, it has fewer mechanisms, making it a more accessible piece of equipment.。 It is recommended when you want to process a large quantity of fewer varieties of workpieces.。| Standard Specifications | |

|---|---|

| Equipment Series | Fltec-24M |

| Equipment Dimensions | 1510Wx1060Dx1237H (mm) |

| Weight | 800公斤 |

| Power Supply | AC 200 Three Phase |

| Main Motor: 1.5 kW | |

| Pump: 0.25 kW | |

| Plate Dimensions | Φ610 |

| Correction Ring Diameter | 外徑 φ280 x 內徑 φ247 mm |

| Ring Rotation | Natural Revolution |

| Number of Simultaneous Processing | 3 Axes |

| Table Rotation Speed | 0-60 RPM (Revolutions Per Minute) |

| First Start | Slow Start/Slow Stop Mechanism |

| Powder Feeding Method | Auto Fill |

Fltec-06

It serves as a compact benchtop device for research and development.。 It is suitable for wafer polishing, sample polishing, and more.。| Standard Specifications | |

|---|---|

| Equipment Dimensions | 340Wx220Dx320H (mm) |

| Wafer Diameter | φ150(mm) |

| Power | AC100 Three Phase 5A |

| Table Rotation Speed | 0-80rpm Stepless Speed Control |

| Processing Time Setting | 1-999S |

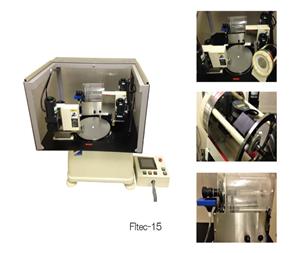

Fltec-15

Desktop equipment for research and development。 It can engage in various research and development activities and offers a wide range of options, even as a desktop unit.。 It cannot handle large workpiece sizes but can perform various polishing tasks.。| Standard Specifications | |

|---|---|

| Equipment Dimensions | 650Wx480Dx340H (mm) |

| Total Size | 870Wx700Dx740H (mm) |

| Weight | About 100 kg(Including PVC cover plate) |

| Plate Weight | Approximately 15 kg |

| Wafer Size | φ380 (mm) |

| Maximum Diameter of Polishing Samples | φ180(mm) |

| Power | AC200 Three Phase10A |

| Table Rotation Speed | 0 to 70 RPM (Revolutions Per Minute) |

| Table Rotation Speed Setting | Volume Setting Digital Display |

| Processing Time Setting | From 1 second (minimum) to 9999 hours (maximum) |

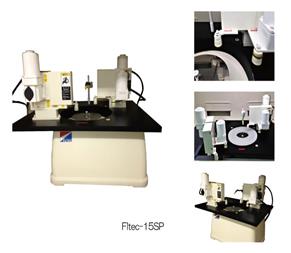

Fltec-15SP

It can engage in various research and development activities and offers a wide range of options, even as a desktop unit.。 Specially designed for specifications in clean rooms.。 It can also be used in conjunction with our laboratory. It cannot handle large workpiece sizes but can perform various polishing tasks.。| Standard Specifications | |

|---|---|

| Equipment Dimensions | 650Wx480Dx340H (mm) |

| Plate Dimensions | 870Wx700D (mm) |

| Weight | Approximately 150 kg (including the plate) |

| Plate Weight | Approximately 30 kg (including the plate) |

| Surface Size | φ380(mm) |

| Maximum Diameter of Polishing Samples | φ180(mm) |

| Power | AC200 three Phase 10A |

| Table Rotation Speed | 0 to 70 RPM (Revolutions Per Minute) |

| Table Rotation Speed Setting | Volume Setting Digital Display |

| Processing Time Setting | From 1 second (minimum) to 9999 hours (maximum) |