Requirements for Polishing Table Surface

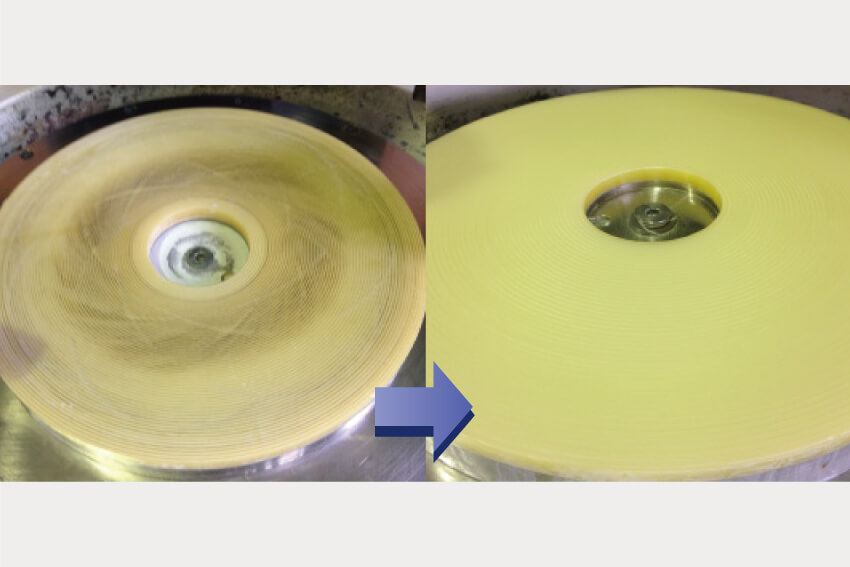

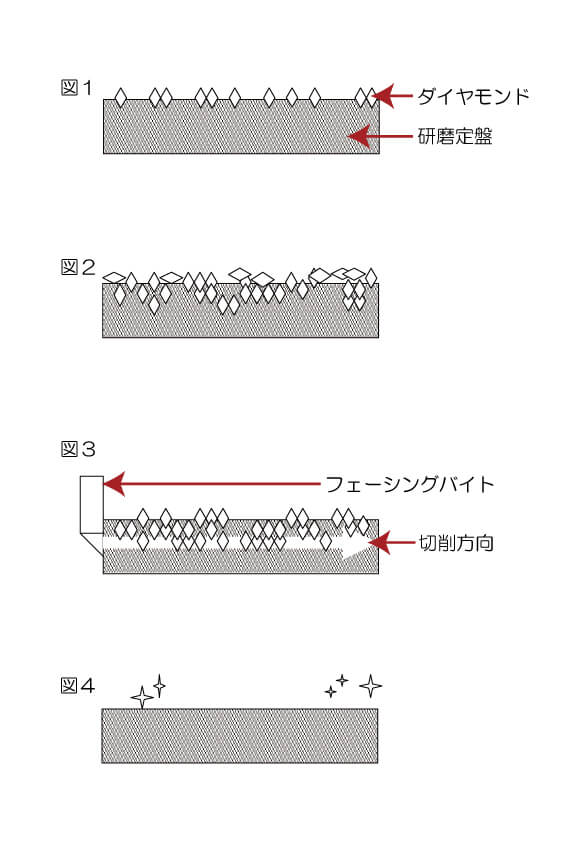

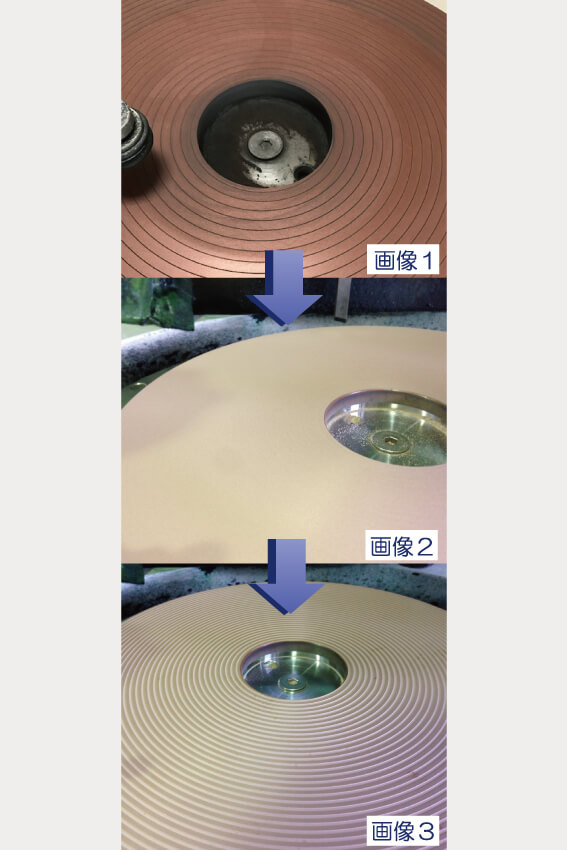

By using fixed abrasives such as diamonds, they can be secured to the polishing platform to polish the target workpiece. (Figure 1)

If the surface is not processed after resurfacing, the diamonds will get clogged, preventing them from being well secured on the polishing disc, resulting in decreased processing rate. (Figure 2)

During end-face processing, in addition to the surface plate with compromised flatness, diamonds that reduce the processing rate are simultaneously cut and corrected. (Figure 3))

After processing, the flatness of the polishing table surface improves, diamonds are secured, and the processing rate increases. (Figure 4))