Achieving the Best Polishing Results

We conduct repeated experiments and trials in manufacturing polishing equipment and polishing conditions。

We will propose the most suitable polishing liquid to meet all materials and required specifications and precision。

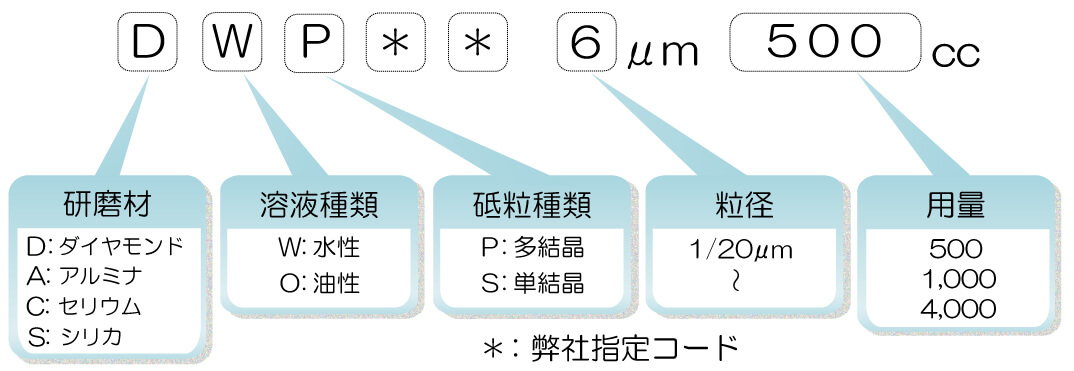

The Four Major Factors in Determining Slurry

| Solutions | Water-Based / Oil-Based |

|---|---|

| Types | Polycrystalline / Monocrystalline |

| Particle Size | Varies by Abrasive (Please refer to the average particle size list below) |

| Concentration | Concentration suitable for customer needs |

Slurry Part Number List

Abrasives

We also only handle grinding materials。

We will select the type and particle size of abrasives that meet your needs。

We will select the type and particle size of abrasives that meet your needs。

[Diamond]

| Particle Size Specification | Average Particle Size (μM) | |

|---|---|---|

| 1/20 | 0-0.10 | 0.05 |

| 1/10 | 0-0.20 | 0.075 |

| 1/8 | 0-0.25 | 0.155 |

| 1/4 | 0-0.5 | 0.375 |

| 1/2 | 0-1 | 0.6 |

| 1.0 1.0 | 0-2 | 1.00 |

| 1.5 1.5 | 0-3 | 1.60 |

| 2.0 2.0 | 0-3 | 1.60 |

| 3.0 3.0 | 2-4 | 3.00 |

| 4.0 4.0 | 2-6 | 4.20 |

| 5.0 5.0 | 4-6 | 5.30 |

| 6.0 6.0 | 4-8 | 6.30 |

| 9.0 9.0 | 6-12 | 9.00 |

Alumina / Cerium / Silicon Dioxide

| Average Particle Size (M) | ||

|---|---|---|

| Alumina /font> | Cerium | Silicon Dioxide |

| 0.1 | 1.0 1.0 | 0.010 |

| 0.2 0.2 | 1.2 1.2 | 0.012 |

| 0.5 | 1.5 1.5 | 0.015 |

| 0.7 | 2.0 2.0 | 0.030 |

| 1.0 1.0 | 0.040 | |

| 1.2 1.2 | ||

| 2.0 2.0 | ||

| 3.0 3.0 | ||

| 4.0 4.0 | ||

| 5.5 5.5 | ||

| 7.0 7.0 | ||

| 12 | ||

| 14 | ||

| 20 | ||

| 30 | ||

| 40 | ||

| 48 | ||

| 57 57 | ||

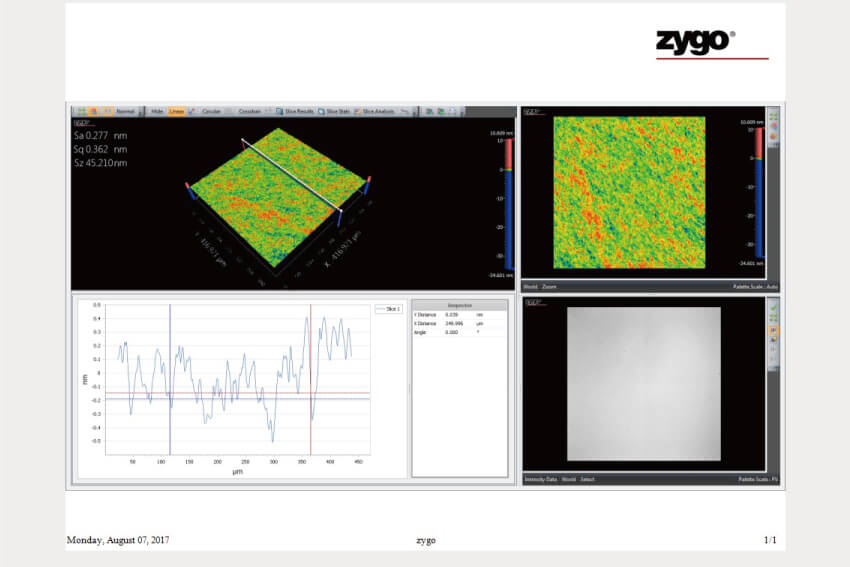

Single Crystal Silicon Carbide Consumables

Developing New Concepts for Abrasive Processing Tests。

he use of these abrasives is intended to replace the "diamond polishing" before CMP (Chemical Mechanical Polishing).。

For example, since this level of gloss can be achieved using only these abrasives,we believe this will address the potential scratching issues caused by diamond abrasives.

Moreover, through the most important feature of "using a hard polishing machine,"the flatness of the chip surface is not a function of the polishing pad ratio, but rather the completion of a flat surface without causing edge sagging.。Scratches will not occur even when using a hard polishing plate.。

The slurry for single crystal SiC does not contain the diamonds found in sintered SiC.。 Unlike polycrystalline materials, single crystal materials do not produce steps, so we are currently customizing them to be diamond-free slurries.。

Unlike polycrystalline materials, single crystal materials do not produce steps,。。

he use of these abrasives is intended to replace the "diamond polishing" before CMP (Chemical Mechanical Polishing).。

For example, since this level of gloss can be achieved using only these abrasives,we believe this will address the potential scratching issues caused by diamond abrasives.

Moreover, through the most important feature of "using a hard polishing machine,"the flatness of the chip surface is not a function of the polishing pad ratio, but rather the completion of a flat surface without causing edge sagging.。Scratches will not occur even when using a hard polishing plate.。

The slurry for single crystal SiC does not contain the diamonds found in sintered SiC.。 Unlike polycrystalline materials, single crystal materials do not produce steps, so we are currently customizing them to be diamond-free slurries.。

Unlike polycrystalline materials, single crystal materials do not produce steps,。。